Aktuelle Nachrichten

-

Neue Einsitzventile INNOVA

22/03/2024INOXPA bringt eine neue Produktreihe von Einsitzventilen auf den Markt, die bedeutende Innovationen und Verbesserungen in Bezug auf Design und Eigenschaften aufweisen.

-

Neues Werk in Frankreich

31/01/2024INOXPA hat ein neues Werk in Frankreich eingeweiht, das eine Erhöhung der Kapazität von Technik und Ingenieurwesen, die Durchführung von FAT-Abnahmeprüfungen sowie Gerätetests und Prüfungen in der Pilotanlage ermöglicht.

Produkte

Fallstudien

Entdecken Sie, wie wir kleinen und großen Unternehmen des Sektors dabei geholfen haben, ihre Ziele zu erreichen.

Bioreaktoren für den Biotechnologiesektor

Entwicklung, Herstellung und Installation von zwei Bioreaktoren für die Produktion von vorteilhaften Mikroorganismen für landwirtschaftliche Anwendungen.

Automatische SLES-Verdünnungsanlage

Maßgeschneiderte Lösung für die selbstständige und sichere Verdünnung von konzentriertem SLES in Verbindung mit programmierten Rezepten...

Nächste Messen

-

Anwendungen

Wir haben die Lösung für Ihr Verfahren

-

Lebensmittelindustrie

-

Backwarenindustrie

-

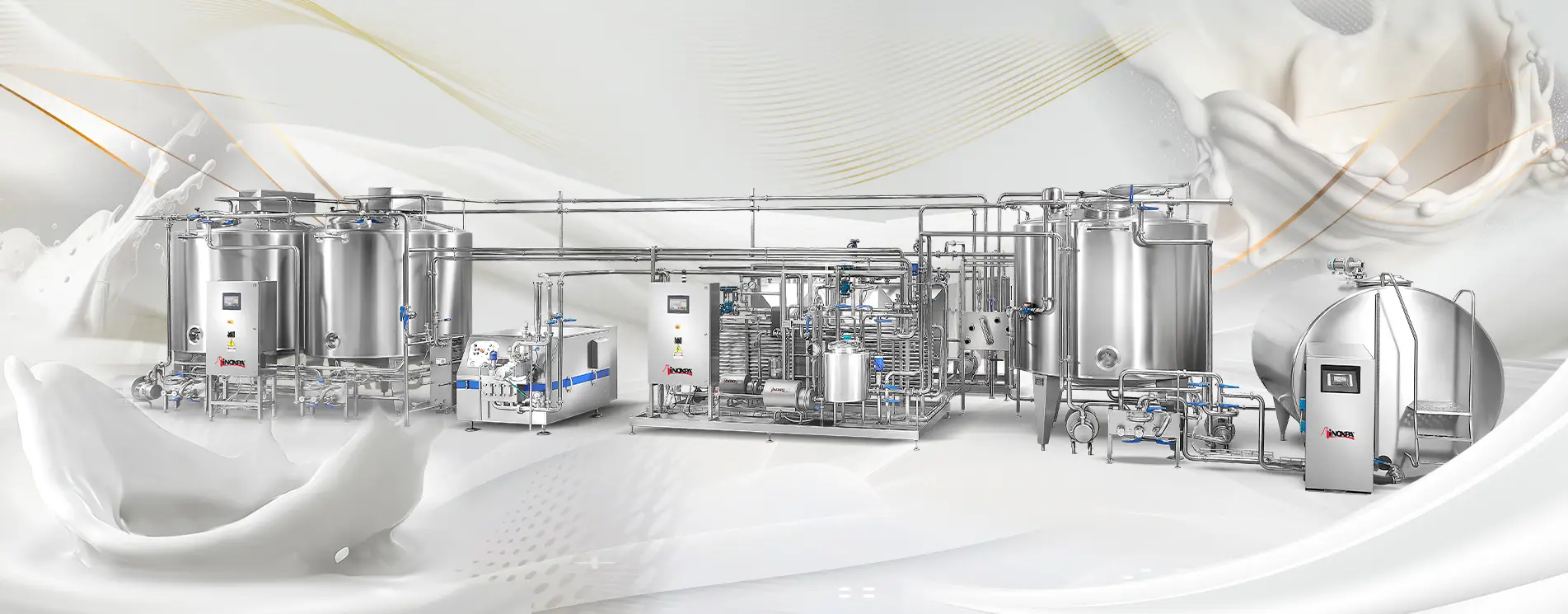

Milchwirtschaft

-

Getränkeindustrie

-

Kosmetik- und Pharmaindustrie

Unsere neuesten Videos

INOXPA zeichnet sich durch die Herstellung von Geräten und Anlagen sowie den Entwurf von schlüsselfertigen Werken aus, die in der Milch-, Lebensmittel-, Getränke-, Kosmetik- und Pharmaindustrie zum Einsatz kommen.

Wir bieten höchste Standards bei Herstellungsprozessen, Installation, Automatisierung und Inbetriebnahme.

Da wir unsere Geräte und Bauteile selbst herstellen, können wir bei all unseren Produkten höchste Qualität gewährleisten.

Dienstleistungen

INOXPA bietet allen Kunden vor, während und nach dem Kauf eine umfassende Beratung und Betreuung. Das gesamte Dienstleistungspaket von INOXPA ist darauf ausgerichtet, dem Kunden dabei zu helfen, schon bei der Produktauswahl das Produkt auszuwählen, das genau seinen Anforderungen entspricht, und dieses Produkt anschließend richtig einzusetzen. Dazu gehören Planung, Installation, Schulung, Problemlösung, Wartung und Reparatur sowie Aktualisierung und Modernisierung.

-

Inbetribnahme

-

Support

-

Verbesserungen

-

Wartung

-

Kundendienst

INTERPUMP GROUP

-

Milliarden € Umsatz

-

Beschäftigte

-

Unternehmen

-

Umsatz in F+E investiert

-

Länder mit Direktvertrieb